Industry 4.0 Labs for Academia

TECHNOLOGY LABS

Marconi Technologies is a technology consulting company focus on Academia & Industry customers to accelerate their digital transformation journey by providing solutions & services related to Product Engineering, Digital Manufacturing, Electric Vehicle, Automation, Robotics, Mechatronics, Cloud Computing & Low-Code Development Platform.

Marconi aims to bridge the gap between Industry and Academia by exploring the latest innovations in Digital Twin of Product, Digital Twin of Production & Digital Twin of Performance. Also provides insights in to how industry trends are reshaping academic curriculum and preparing students for the evolving job market.

We associate with academic institutes to set up Common Engineering Facility Center and Center of Excellence by providing various labs related to Industry 4.0.

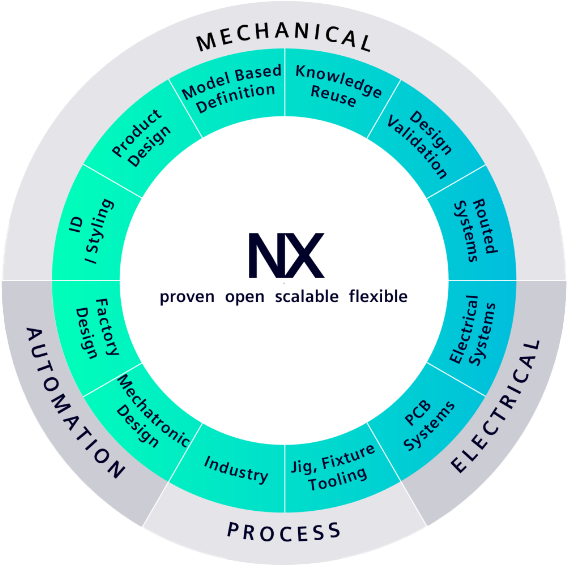

The Product Digitalization Lab equips students with hands-on experience in various aspects of product design, including 3D modelling, 2D drawing, sheet metal design, surface design, PCB design, computer-aided manufacturing, and piping and electrical routing design. It’s an exciting opportunity for students to bridge theory and practice in the world of engineering and manufacturing.

The Product Digitalization Lab harnesses SIEMENS’ NX software—a powerful tool for product design and engineering. With NX, students delve into 3D modelling, simulation, and various design aspects, bridging theory and practical skills.

Design more efficiently with NX than any competitive software

The world’s most productive modeler has an intuitive interactive user interface and the fastest model resolution to help you go from concept to model reality in the shortest time possible.

Design Versatility – “You can work in a more innovative way, combining the capabilities of Alias, SolidWorks, and Space Claim in a single tool.

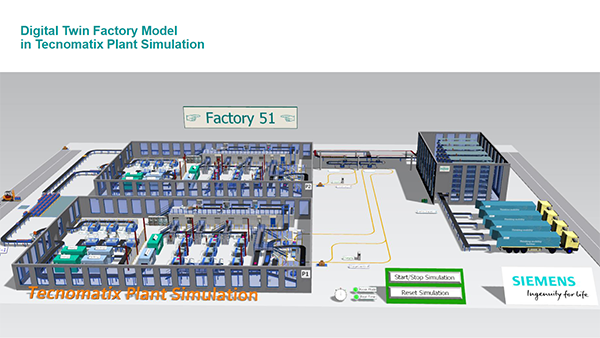

The Digital Manufacturing Lab equips students with industry-ready expertise in planning, simulation, validation, and optimization of product assembly processes and production systems.

The Digital Manufacturing Lab bridges the gap between classroom theory and real-world challenges. Students emerge with a holistic understanding of production systems, ready to contribute to the ever-evolving manufacturing landscape.

So, imagine students huddled around computer screens, tweaking assembly line layouts, analyzing data, and envisioning smarter factories. It’s where theory meets nuts and bolts—a place where innovation thrives.

The Digital Manufacturing Lab leverages Siemens’ Tecnomatix Process Simulate and Plant Simulation software. With these powerful tools, students dive into virtual production system modelling, process optimization, and real-world simulation. It’s like having a digital factory at their fingertips!

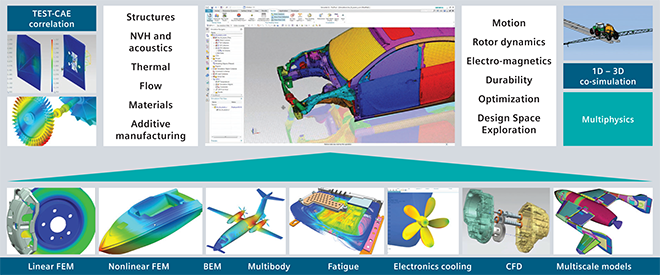

The Engineering Simulation Lab empowers students with predictive analysis skills for design functionality. They explore system simulation, multiphysics modeling, and even delve into the fascinating world of NVH (noise, vibration, and harshness).

Engineering Simulation Lab provides specialized training in two powerful Siemens software tools: Simcenter 3D and Amesim.

Simcenter 3D: The most comprehensive, fully-integrated CAE solution.

Simcenter 3D addresses complex product engineering processes by delivering revolutionary improvements in simulation efficiency. With advanced capability 3D simulation technologies and a comprehensive range of CAE applications, Simcenter 3D offers new methods that increase realism and deliver better insight into your product’s performance. Simcenter 3D captures expert knowledge and best-practice workflows, enabling engineers and analysts to collaborate on a platform that accommodates all aspects of functional performance.

Simcenter Amesim™ software is a leading integrated, scalable mechatronic system simulation platform that allows design engineers to virtually assess and optimize system performance. This boosts overall systems engineering productivity from the early development stages until the final performance validation and controls calibration. Therefore, Simcenter Amesim can be your tool of choice to develop successful.

NVH Test Lab offers you a complete, integrated solution for test-based engineering that combines high speed multi-channel data acquisition with a full suite of integrated testing, analysis and report generation tools.

Enhance testing processes and boost productivity and product innovation with Simcenter Physical Testing. Our solutions integrate multi-physics data acquisition hardware with a complete suite of data management, analytics, and modeling software, covering a wide range of test needs.

Additive Manufacturing Labs provide students with hands-on experience in 3D printing. These labs break free from traditional tooling constraints, allowing students to build intricate geometries layer by layer.

This lab offers students hands-on 3D printing experience, liberating them from conventional tooling limitations. Students can create intricate geometries layer by layer. Marconi provides printers using technologies like Fused Deposition Modeling (FDM) and Multi Jet Fusion (MJF). In these labs, students design parts in the Product Digitalization Lab and swiftly produce prototypes for instant design evaluation. It’s a creative journey where ideas materialize.

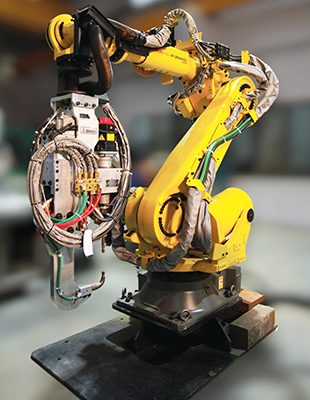

The Industrial Robotics Lab provides students with comprehensive, hands-on experience in programming various industrial robots for applications such as arc welding, spot welding, and material handling. These robots are integrated with Tecnomatix Process Simulate software, allowing students to create offline programming and implement it on real robots.

Industrial Welding Robo Cell consists of 3 individual experiment tables and an industrial welding robot with minimum reach of 1000mm. Central Control Unit equipped with PLC, HMI and IIOT is integrated with Welding Robot. Robot can be programmed from a teach pendant or from an offline programming software which can also act as a digital dynamic twin.

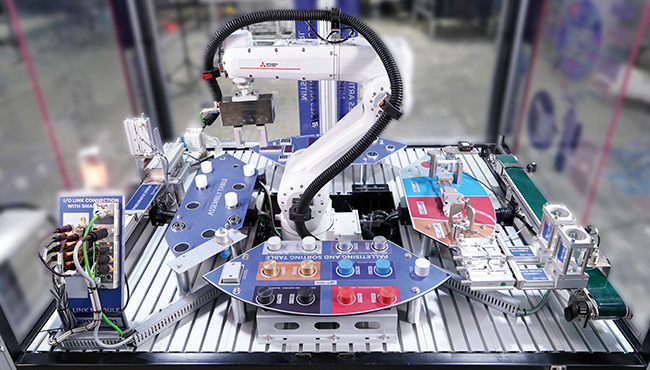

Handling Robo Cell is an industrial 6 Axes articulated robot with minimum reach of 700mm and payload capacity of 7 KG. End effector is electrically actuated. Communication between Robot Controller and machine control panel is via profinet. Various sensors such as colour sensor, photo sensor communicate with PLC through io link protocol.

Spot Welding Cell is a training cell with a SPOT welding Robot integrated with PLC – HMI and IIOT. Participants can carry out automated welding in integration with Servo Motor as well. Three experiment tables provide hands on experience on horizontal as well as vertical spot welding. Separate Central Control Unit with workstation and dual monitors provides easy access for the robotic as well as PLC programming.

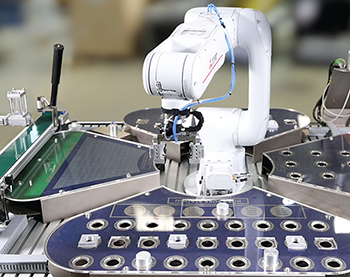

IIoT Mechatronics Lab is equipped with Smart Factory from IIoT based flexible manufacturing system. Entire system consists of 4 modular stations along with a fifth station which is a robotic gantry. Each station can be operated in individual mode as well as in integration mode. Bearing assembly is carried out with the help of pneumatic gauging, vision inspection as well as barcode reading. Robot (7 Axes Robot with Linear gantry axis) is fully integrated with the smart factory through SCADA and MES. Production optimisation system along with Automatic Storage and Retrieval System is also provided in the system with photo sensors. The entire system operates on a SCADA which can be programmed by the users along with MES (Manufacturing Execution System).

Smart factory is also equipped with remote commissioning software (Siemens Mechatronics Concept Designer) and Siemens Technomatix which acts as a digital dynamic Twin with factory simulation. Users can design entire PLC ladder in 3 dimensional workspace in Siemens NX MCD.

Industrial Automation Lab focuses on hands on training on operations of PLC, HMI as well as most commonly used industrial automation components in integration with PLC and HMI. Training kits equipped with basic and advanced PLCs such as SIEMENS S7 1200 and S7 1500.

Automation modules include Servo Motor Module, Temperature Control Module, AC Motor and VFD Module, External Encoder Module, Color based Sorting Conveyor module.

Advanced Pnuematics training system is computer-controlled PLC based pneumatic training solution. The training system is dual faced system made of industrial grade heavy duty aluminum extrusions. Castor wheels with rigid mounting provision are provided. Top, bottom and 4 drawer pedestal in industrial MDF are provided for convenient operation and storage of items.

PLC Input and out modules are provided on the control panel to which the inputs and outputs of PLC are hard wired. Field input and field output modules are hardwired with the field components such as solenoid valves and reed switches through industrial sensor terminals. Industrial connector based wiring makes it easier for users to understand and maintain the training system.

Advanced Hydraulics Lab is designed to provide complete training on Hydraulics where participants start from novice and are expected to reach the expert level. This lab is equipped with electrohydraulic training kit is provided with advanced level conventional valves, solenoid valves, pressure switch as well as the PLC. Participants are expected to operate advanced hydraulic valves in collaboration with PLC. All necessary accessories such as input and output modules are provided to make it easily operable for participants.

As welding techniques become more sophisticated, training methods need to keep pace. One innovative approach that has gained traction in recent years is the use of welding simulators. These devices are not only improving training efficiency but also significantly enhancing knowledge retention among welding trainees. Traditional welding training often involves live demonstrations, classroom instruction, and hands-on practice in welding booths. While these methods are effective, they have several limitations such as safety, Resource-Intensive and limited immediate feedback. Simulation is driving a new era of education, allowing learners to practice in controlled, engaging, and effective environments that foster long-term retention and skill acquisition.

LMS system of this equipment allow instructors to centralize all this information in one place, visualizing the completed practices and even replaying them. It also generates individualized performance graphs, promoting healthy competition among students. Moreover, these tools enable the creation of custom courses, combining theory, practical exercises, and tests. This comprehensive approach integrates multiple aspects of the learning process, ensuring students not only understand the theoretical components but can also apply them practically.

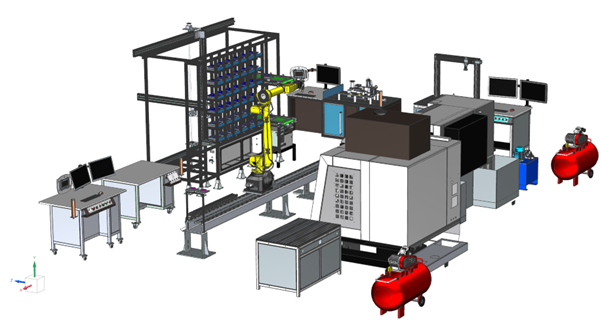

Smart Integrated Manufacturing Lab

Digital Factory is a Smart manufacturing setup integrated with SCADA, Digital Twin and OPC UA. The entire system is powered with open architecture such as PLC and SCADA from Siemens. CIM can be very easily integrated with other factory automation products such as CMM, RPT or even additional CNC Machining centers. Various sensors are provided to collect data points which can be used for generating ‘Artificial Intelligence’. The system is compatible with digital twin software which can be integrated with OPC UA. The complete system is equipped with IIOT hardware with dedicated cloud space for remote monitoring as well as data storage. The entire system can be controlled remotely through IIOT.

This is a fully functional electric vehicle lab that empowers students to build, wire, diagnose, and program an EV while practicing low and high voltage safety procedures. A high-impact project that challenges students to build, test and drive an electric vehicle as an educational project.

This EV Lab is the perfect workforce development tool for educators to teach hands-on EV fundamentals. Designed using a component-agnostic approach, it prepares students for careers in electric vehicle technologies.